Rulon extends bearing life from months to years

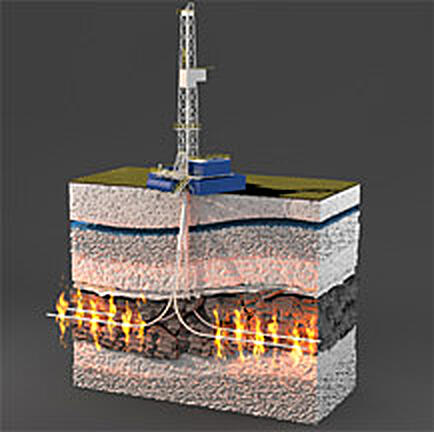

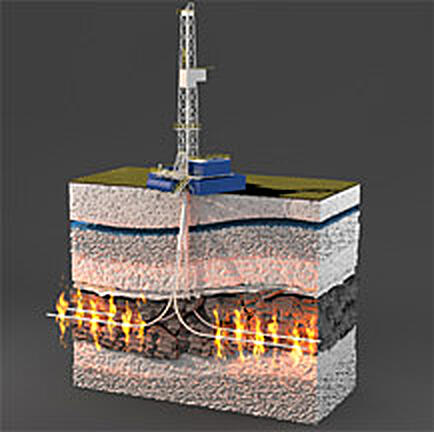

Hydraulic fracturing, hydrofracking or “fracking” is a newer technology employed by the energy industry to reach natural oil and gas supplies trapped deep within the shale level of the earth. The process involves drilling thousands of miles underground to fracture shale rock, which allows oil and gas to flow to the surface for collection. By reaching natural reserves which were once thought to be inaccessible, fracking is credited with lowering US dependence on foreign energy supplies.

This tough application depends on a complex assembly of drills, pumps and hydraulic systems; some requiring literally hundreds of bearings. The equipment must endure 24/7 operation under extremely harsh conditions, including temperature variations, thermal expansion and extreme loads. Not all bearings are up to the demand ― but Rulon excels in it.

Carbon graphite bearings wear prematurely

As a longtime partner to oil and gas OEMs, Tristar engineers worked with the designers of fracking compressors seeking an alternative to their carbon graphite bearings. They cited how the graphite failed prematurely from the high-pressure cycling and required replacement every 3-4 months. This maintenance schedule drained resources and lowered production levels. Our client also noted they had experimented with glass-filled bearings with equally-dismal results.

Rulon 945 for impact and longevity

Rulon 945― a material designed specifically for the oil and gas industry ― was up to this tough challenge. Boasting exceptional impact stability, plus heat and chemical resistance, 945 provided an ideal fit for high-frequency cycling. The material’s unique fillers deliver one of the lowest deformation rates under load (< 1%) for extreme conditions.

Since switching to Rulon 945, our client reports their bearing longevity has extended from 3-4 months to 2-3 years. Rulon 945 stays the course in extreme conditions; see our Rulon Comparison Chart to explore the advantages. Or Ask the Experts for a custom consultation.

Want to share your experience with oil and gas bearings? Join the conversation on our Tech Talk blog today!